Corporate social responsibility (CSR) has fizzled out, long live the circular economy! This is what politicians, newspaper headlines and advertising posters that accompany our daily lives seem to tell us. What if the two concepts were just two sides of the same coin that every company seeks to achieve to remain competitive and meet society's expectations? Entering into a circular economy approach is a winning strategy for businesses, including SMEs. Update with Catherine Viale, consultant and trainer.

“Extract, manufacture, consume, throw away” sums up the dominant linear economic model well. Its multiple negative impacts on the environment and health are today indisputable. No one – or almost no one – doubts its cause and effect link with climate change and the loss of biodiversity.

Currently, certain resources essential to economic recovery are in short supply. That is to say: wood, construction materials, paper, aluminum, vinyl, wheat or even semiconductors. This shortage highlights the rigidity of supply chains and the fragmentation of value chains. Indeed, design, extraction, manufacturing and services are found separated in different countries, themselves often far from places of consumption. The ecological and economic issues have therefore come together until reaching a consensus: the circular economy must be the pillar of a new social project, at least at the European level.

But what does the circular economy consist of?

It's a “economic model whose objective is to produce goods and services in a sustainable manner”. How ? “By limiting the consumption and waste of resources (raw materials, water, energy) as well as the production of waste. » This is the definition given by the Ministry of Ecological Transition. And it is with this in mind that companies must put themselves in working order.

The seven pillars of the circular economy

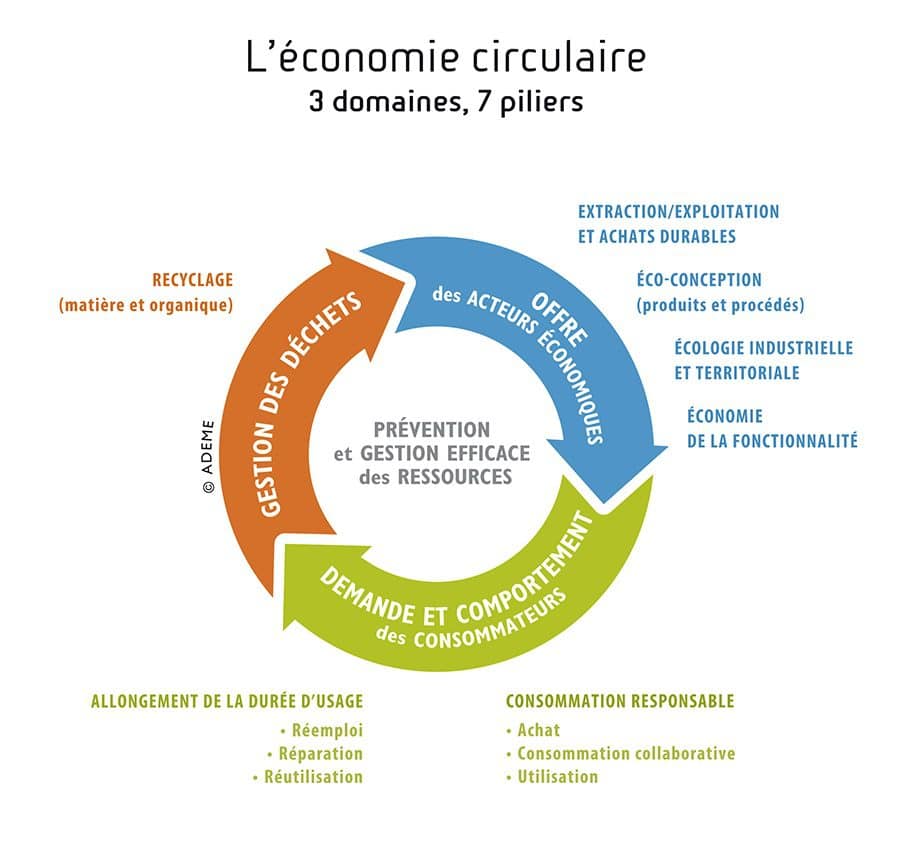

When we talk about the circular economy, we tend to equate it with the recycling economy and efforts made in terms of energy efficiency. Although encouraging, these two fields of action are not sufficient to resolve the equation between sobriety and value creation. This is why the Ecological Transition Agency (ADEME) has implemented the principles of the circular economy according to seven pillars. Closely linked, they are also based on collaboration between the different actors in the value chain.

Thus, any transition project towards the circular economy requires rethinking each step taken to produce a good and deliver it to the customer. In other words, from design to final use and beyond. This very often requires developing employee skills through training activities.

Some examples of training:

| SKILLS to acquire or develop: | Training: |

|---|---|

| Eco conception | Ecodesign of digital services |

| Responsible purchasing | Reconciling purchasing performance and CSR issues Responsible IT purchasing |

| Waste management | Reconciling prevention and waste management with a view to a circular economy Manage waste from economic activities in compliance with French regulations |

| Regulation | Implementation of a corporate environmental policy Environmental law for non-specialists |

| Project management | The fundamentals of project management Project management, advanced |

| Innovation | Working with suppliers to innovate |

| Communication and marketing | CSR communication: enhancing your company’s image Sustainable and responsible marketing |

How to actually take action?

But from what angle of attack should we start thinking and define our priorities?

Many companies positioned on the subject focus on recyclability (25 %) and extending the lifespan of the products they manufacture (34 %). And this is working quite well for them, according to a study by the National Institute of the Circular Economy (INEC) and the consulting firm OPEO (April 2021).

Optimize waste management

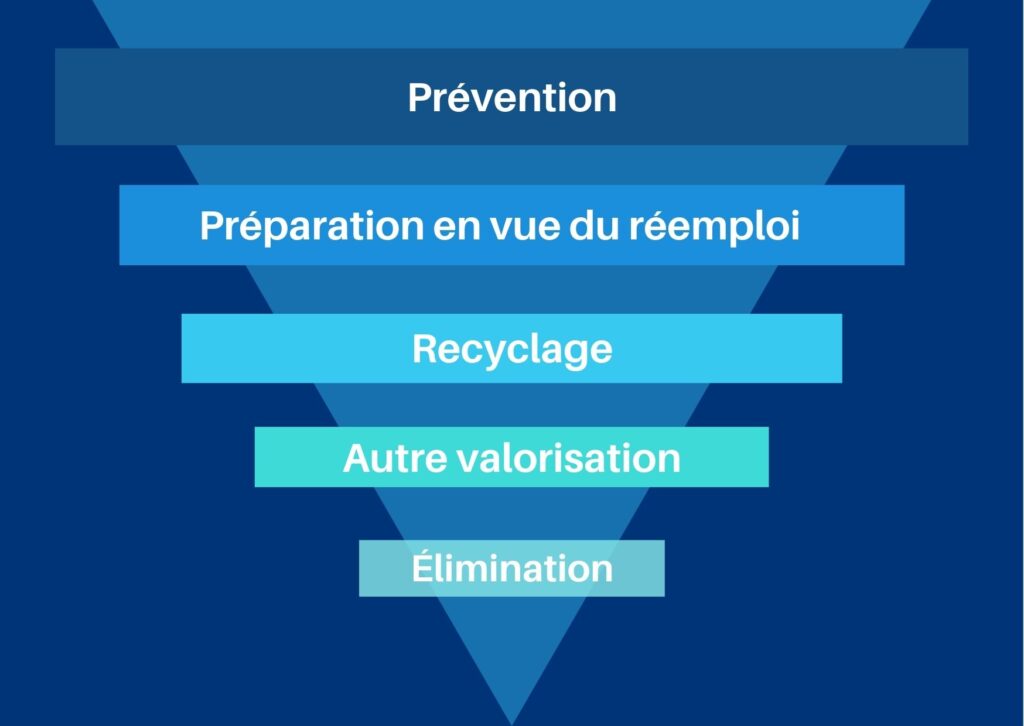

A company that wants to enter the circular economy therefore benefits from exploring different solutions to optimize the management of its waste. For this, it can rely on the preferential waste treatment hierarchy advocated by the environmental code (see below).

The preferential hierarchy of waste treatment

The challenge ? Onboard all company stakeholders in the search for “economically acceptable” organizational and technical means to achieve a level of n-1 management for all waste. The idea is to proceed step by step until they are reduced at source. Because it is well known that “the best waste is that which is not produced”, particularly because it costs nothing.

Calculate the true cost of waste

As such, the MFCA (Material Flow Cost Accounting) method defined by standard ISO 14051: 2011 makes it possible to calculate the full cost of waste. It shows quite quickly that the submerged part of the financial iceberg is not where we think. Indeed, choices in terms of design, purchasing of raw materials and transport logistics have at least as much impact as manufacturing and sorting operations on the quantities of waste generated. Ultimately, these choices often weigh much more heavily than the bill for disposal providers.

Extend the life of products

Another way to reduce your ecological footprint and costs is to divert end-of-life products from waste status. A status which is not only synonymous with loss of value but also very restrictive from a regulatory point of view. To do this, the company must broaden the consultation of its suppliers and customers to other actors likely to consider its waste as wealth. It can do this either directly or through organizations such as consular chambers, business clubs or economic development agencies. The key idea is networking from a territorial industrial ecology perspective. So, the circle is closed!

Circular economy and SMEs: very real advantages

Implementing a circular economy project may seem like a relatively heavy investment for a small business. However, it presents very real advantages, such as better cost control and increased competitiveness.

Conquer new markets

Engaging in the circular economy means anticipating normative and regulatory developments rather than undergoing them. It also means placing yourself in the field of innovation and becoming a pioneer in a system destined to evolve. Even conquer new markets.

One of the most striking examples is the success of shopping bags, water bottles, mugs and other everyday objects, which are gradually replacing single-use plastic packaging and tableware. And this, under regulatory pressure and public opinion.

Reputation and attractiveness

In turn, going green in its practices and offering improves the reputation and attractiveness of the company. On the one hand, among younger generations of consumers concerned about “responsible” consumption. On the other hand, with employees who wish to give meaning to their professional activity.

A medium-term strategic vision

On the decision-makers' side, engaging in this approach implies having a medium-term strategic vision to detach themselves from the immediate constraints of their market segment. This also requires a desire to anchor their business in the region by favoring short circuits and creating non-relocatable jobs.

Partnerships

To claim effectiveness, the circular economy cannot be the result of the addition of isolated initiatives. On the contrary, it is based on cooperation between different sectors via intereconomic partnerships, at the origin of new business models. As an example, let us cite the explosion in the bicycle rental and repair offer driven by associations and craftsmen as well as by major sports brands over the past ten years.

To conclude, optimizing waste management is only one part of the circular economy. But it is nevertheless this approach which remains the most concrete to bring about a change in behavior. In fact, it allows all professions to be involved with the environment and quality departments in a holistic analysis of the company's processes. Namely: buyers, design offices, operators, maintenance, logisticians, salespeople, etc.

Meeting the need for resilience in the face of finite resources often requires questioning the company's business model. Of course, revising the organization, technologies and know-how generates significant costs. But 85 % of companies that have taken the plunge consider that it is a real opportunity for their competitiveness and the development of new markets (INEC and OPEO study).

As part of the recovery plan, 350 million euros aims to support the circular economy. Support measures financed by ADEME are aimed at SMEs, VSEs and social and solidarity economy organizations.

Now is the perfect time to get started!