Total cost of ownership (TCO) is becoming a strategic lever for purchasing, industrial and financial departments. Behind an attractive purchase price often lie invisible costs that have a lasting impact on a company's performance. Against a backdrop of pressure on margins and a drive for efficiency, how can we move from a price-centred approach to a global, operational analysis of costs over the entire life cycle? Alain Wolgensinger, a specialist in optimising sales performance, provides an overview. With a 4-step methodology, practical examples and best practice, find out how TCO can be used to secure purchasing decisions and boost your company's competitiveness over the long term!

Did you know? According to the experts, 70 % of the costs of a purchase are invisible on the quotation. In industry and logistics, where every euro counts, Total Cost of Ownership (TCO) is becoming the ultimate weapon for savvy buyers. Here's how to use it in practice.

TCO decoded: the iceberg of real costs

TCO: what is the definition?

Total cost of ownership. This is simply the total cost of a good or service over its entire life cycle, including all costs, including hidden costs, like an iceberg.

This echoes the common sense adage of our ancestors:

«Price is forgotten, quality remains».»

According to them, a low price hides a mediocre quality which will be paid back in fine.

Industry and services are full of such examples.

1/ A welding robot with integrated remote maintenance service, which is more expensive but guarantees better predictive monitoring and faster intervention, and therefore more operational time billable to customers.

2/ A vehicle in a higher range but offering better resale value and less costly maintenance and spare parts than an entry-level vehicle.

[Anecdote] A CEO once expressed his surprise and annoyance that his beautiful German car was costing him much less each time he went to the garage than the French makes of his sales staff's cars. He seriously considered switching them to the same range, but then thought again: what would customers think of such luxury?

3/ A dustbin purchased by the general services employee of a municipality on the Internet, ultimately less expensive than buying from a local shop yet €20 cheaper, due to lower administrative costs.

[To remember] In technical terms, we talk about cost of placing orders. Economists typically estimate it at between €50 and €150 per order, regardless of the amount ordered. The cost of placing an order is also a fundamental data for calculating the QEC. In other words, the economic order quantity, which minimises the total cost of inventory.

4/ Services The undeniable cost of these services is offset by the undeniable benefits they bring to employees: greater availability at work, reduced mental workload, preserved physical capital... with the corollary of increased productivity.

So how do you make sure you're on the right track?

4 steps to an efficient TCO

Step 1: draw up a complete cost map

Step 2: carry out accurate modelling

Step 3: building teams

Step 1: Draw up a complete cost map

Le purchasing department is clearly the best place to start. So how do you go about it?

First of all, list all visible and invisible costs. Best practice: involve the «technical» departments» to draw up or add to this list: maintenance, logistics, HR, etc.

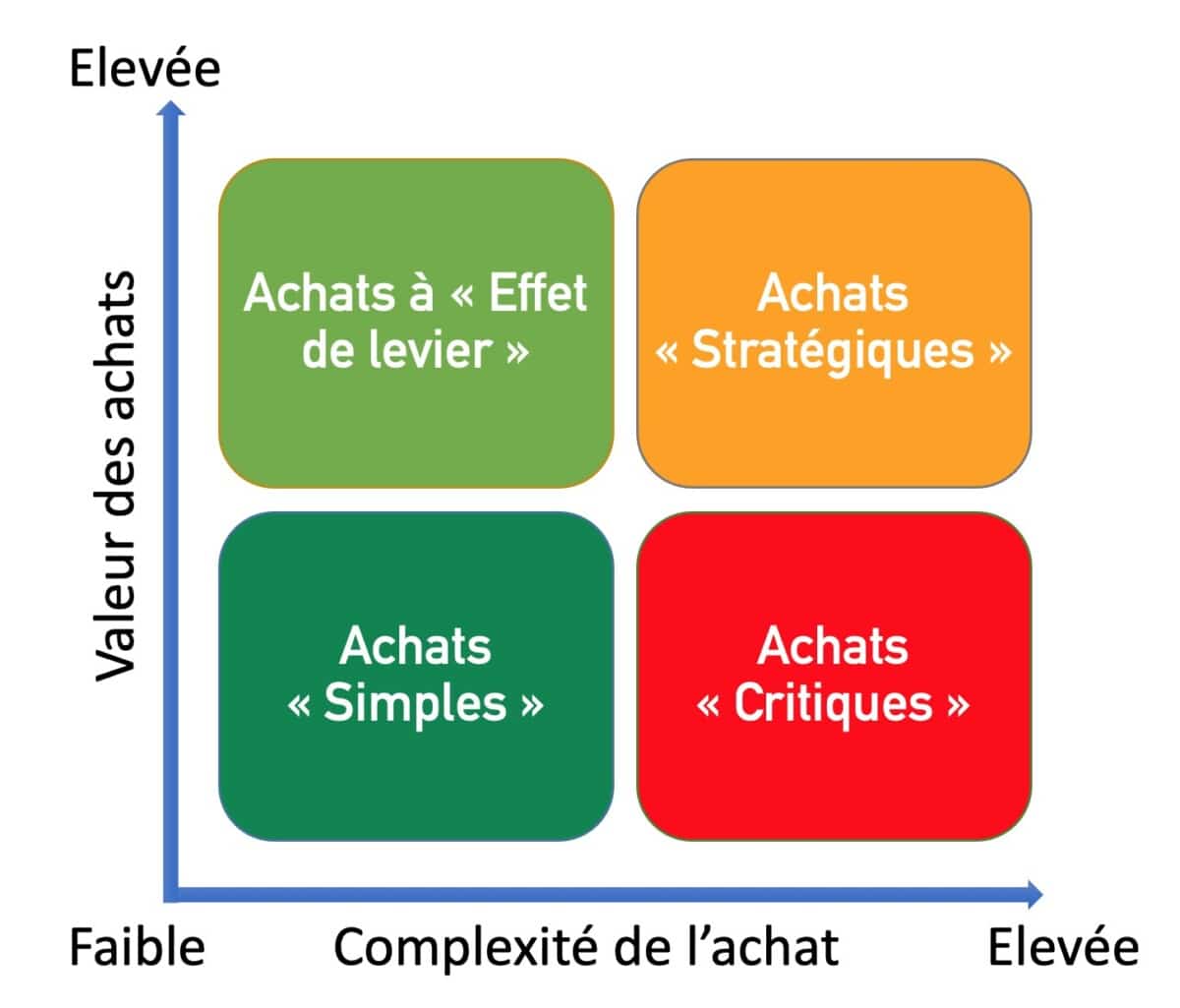

And then.., systematize the TCO approach on strategic or critical purchasing, because they are more complex to treat, cf. matrix Kraljic.

[Also read] Negotiating purchases: best practice

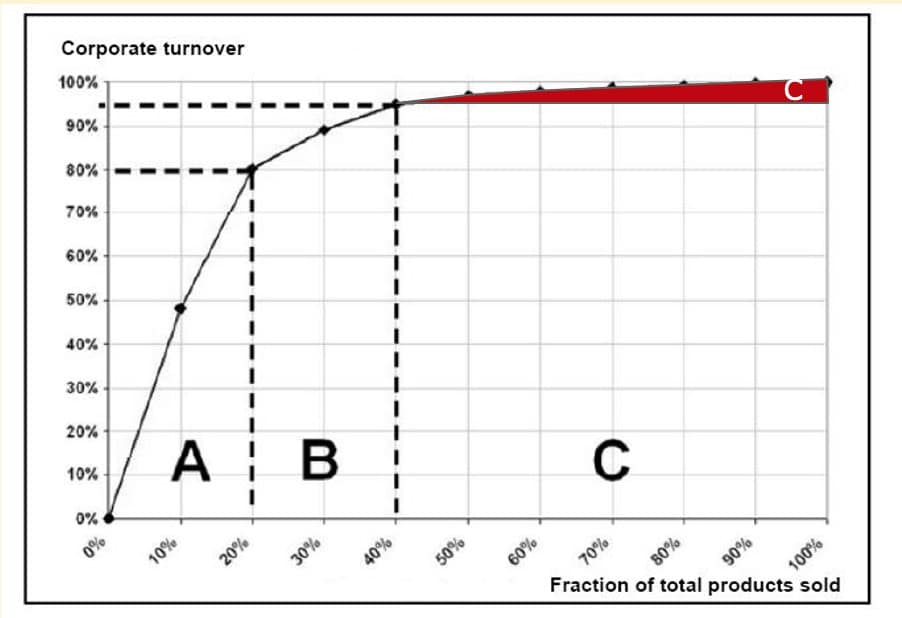

Ideally, also include articles from class C (ABC diagram).

These are often considered unnecessary, but ultimately burdensome because they are purchased indiscriminately (outside the controlled purchasing process) and administrative costs are too often underestimated. For example: office supplies, receptions and daily consumables (sugar, coffee/tea, cups, etc.).

[Real case] Judging that it was spending too much time on office supplies, one company decided to take out a subscription with a nearby shop. Like a vending machine operator, the shop visits every month and replenishes the office supplies in the quantities required. It then invoices the customer. To avoid price fluctuations, a price was agreed at the beginning of the year. Any price increase of more than 10 % must be reported. The company said it was delighted to no longer run the risk of running out of stock, while at the same time reducing its mental workload.

Step 2: carry out accurate modelling

Here again, this formalisation will logically entrusted to the purchasing department.

- Using sector templates

For example: typology and orders of magnitude of associated costs for machines, vehicles or training. In other words, cost versus employee satisfaction rate, or even productivity increase in % obtained after the event, etc.

- Preferably include 3 scenarios: optimistic, realistic, pessimistic

For example: the resale of TESLA electric vehicles, once highly prized, has become more problematic as its leader's image has been tarnished by the short-lived DOGE (Department of Government Efficiency) within the US administration.

[A surprising example]

Detailed analysis of TCO costs and return on investment calculations can produce astonishing results.

A car parts manufacturer, appalled by the extra insurance costs incurred by its employees following an accident at work, introduced a quarterly presenteeism bonus. This means x days' attendance over the period, with no absences caused by an accident at work. Employees are now so vigilant that :

1/ Accidents have become rarer.

2/ Attendance has increased, and with it production.

3/ We even had to insist that «minor» but unavoidable accidents (nicks, small cuts, etc.) were not ignored, in order to protect the health of our employees.

4/ The premium was - clearly - offset by these savings and gains.

A clear win-win TCO!

Stage 3: Forming teams

This task, logically entrusted to the purchasing department, This will require an internal memo from management to underline its importance. Similarly, the creation of one or more «TCO referent» in the departments concerned. For example: purchasing, accounting, etc. Finally, it will be a matter of proposing practical workshops with case studies, incorporating real costs as faithfully as possible and testimonials from TCO referents.

The feedback from the field can be spectacular and rapid. A site manager explains:

«Our junior buyers now identify twice as many hidden costs.»

[Training reflex]

The fundamentals

A well-structured purchasing function is a major driver of business performance. Would you like to acquire a clear and operational vision of the business? Our training The keys to the purchasing function enables you to situate the purchasing function within the organisation, understand the economic issues involved, particularly the impact on profitability, and master the entire purchasing process.

The negociation

Successful purchasing negotiations rely on a fine blend of technical expertise and communication. To learn more about best practice, take our training course Negotiating your purchases more effectively It gives you the keys to preparing for negotiations, getting to know your supplier and its offering better, identifying negotiating levers and defining objectives in line with your company's strategy.

Responsible purchasing

Integrating social, environmental and ethical criteria into purchasing decisions reduces risk, stimulates innovation with suppliers and strengthens brand image. Want to improve your company's overall performance through responsible purchasing? Discover the training programme. Responsible purchasing: reconciling purchasing performance and CSR issues.

Step 4: Regular monitoring and communication

This is a fundamental point, because what can't be measured can't be improved!

So how do you go about it?

- Via quarterly dashboards (monthly, they run the risk of being poor in content

- Quarterly reviews with the Finance Department to detect any deviations from an overly optimistic or pessimistic vision

- Provide a Key KPIs Difference between planned and actual TCO (<5 % = target)

Checklist: 4 questions + 1 attitude

Your company's approach and relationship with its suppliers will change!

To do this, you need to install 4 key questions.

1/ What is your commitment to the product's lifespan?

- First, compare warranties between products. For example: 5 years versus 2 years.

- What about extended warranties or preventive maintenance contracts?

- Then evaluate the costs over 3/5/10 years.

2/ What are your average breakdown rates and response times?

- Make sure you have these (reliable) figures.

- Insist on customer references: telephone numbers of buyers or clients.

- If the supplier is a new candidate, ask for independent laboratory tests or consider a simple trial order to check its solidity.

- Favour remote repair solutions (remote maintenance).

- Calculate the impact of downtime in terms of both operating costs and lost sales.

3/ Are your products able to keep pace with new regulations?

The aim is to anticipate the costs of updating, which are often underestimated.

[Real case]

The director of a communications agency congratulated himself on having opted for Apple computers, both for his graphic designers and for the rest of his staff.

Admittedly, the purchase price was much higher than for competing PCs running Windows (50 to 75 % more). But all the staff had noticed that they no longer had to worry about endless updates. They no longer feared losing data during this critical phase. What's more, the highly connected environment made transfers easier. Some had even given up using the mouse in the face of the Trackpad's efficiency.

The TCO may be unquantifiable, but it is far more favourable than expected in terms of costs saved, making it impossible to turn back the clock!

4/ What is your end-of-life take-back/recycling policy?

It is essential to’include decommissioning costs.

LOA (lease with option to buy) is the solution proposed by a banker to relieve his customer of the burden of dismantling: if the customer does not wish to buy the object (machine or vehicle in general), the banker recovers it.

Suggestion: ideally, include all the TCO criteria in the supplier selection grid.

[1 complementary attitude]

You must complete these 4 questions with a an attitude of attentive but critical listening.

It's worth noting that a salesperson worthy of the name will first have identified the arguments that make the vehicle competitive outside the price range. He or she will then list all the elements that enter into the TCO.

For example case of a sales representative at KUBOTA, a crane manufacturer.

For the sale of work optimisation solutions, it lists :

- improved productivity (faster, safer working, fewer delays)

- greater profitability (fewer late penalties)

- but also a better image (less discount on resale than the Chinese competition, despite being 40 % cheaper!)

But these presentations could «forget» the arguments that are more unfavourable to them or the numerical evidence.

As a result, the TCO-savvy buyer won't forget to also collect the negative (the hidden costs).

For example:

«What are the main shortcomings of your product, apart from the price?»

«What are your unhappy customers saying?»

«Who can validate what you're telling me?»

Take action!

For optimum results, use a variety of tools and approaches!

IT tools

A number of TCO software packages exist, targeting the needs of both SMEs and large groups. They are easy to find on the Internet, but it's a good idea to ask for advice from users.

Training in the basics of the TCO approach

As early as the onboarding stage, introduce your new recruits to the TCO approach (in the welcome booklet, for example).

A change of mindset

Firstly, among your employees within the company, who will be encouraged to move away from buying on the spur of the moment or price-focused purchases to well-considered purchases that integrate benefits and hidden costs.

A delegation likely to be in the start-up phase

Stages 1 and 2 - cost mapping and modelling - can sometimes take a long time to complete, but can perfectly well be entrusted to a junior buyer duly coached by a manager.

Ongoing management of the TCO approach

To keep this demanding approach alive and avoid the pitfalls of passing fads, share your experience with other companies.

Ask your professional organisation or CCI for testimonials. They often open up new avenues, like some of the examples given above.

A few points to bear in mind for an informed TCO buyer

- Of course, we shouldn't be naive. Firstly, the digital ordering could complicate the lives of local suppliers, who are often essential to the day-to-day running of the business.

- Secondly, costs are sometimes difficult to assess, Especially when they only become apparent with use. And some gains are not there.

- competition, Once lagging behind, China can also make progress. This is the emblematic case of Chinese electric cars: initially praised for their affordable price, some now claim that they are better than European manufacturers. So their TCO is improving!

- Finally, the pressure on prices is strong, and is often necessary for customers with tight cash flows. Under these conditions, the TCO approach is not for them.

However, if this TCO approach had been generalised earlier, it is likely that «Made in» would be less concentrated on other continents, given that hidden ancillary costs are better taken into account.

Ultimately, TCO is a real competitive lever. It is both a CSR-compatible approach and one that is concerned with efficiency (getting the most for your resources) and security. By avoiding naivety and adopting a pragmatic approach, buyers strengthen their role as economic strategists, capable of informing the company's decisions over the long term and actively contributing to its sustainable performance.